Our Products

- SINGLE POINT DRESSER

- MULTI POINT DRESSER

- IMPREGNATED DIAMOND DRESSER

- DIAFORM CHISEL POINT DIAMOND DRESSER

- CHISEL POINT DRESSER

- CONICAL DRESSER

- FORM DRESSER

- ROCKWELL INDENTORS

- PCD / CBN inserts for turning, boring milling

- PCD / CBN grooving tools

- PCD / CBN turning tools

- PCD / CBN milling tools

- PCD / CBN microbore tools

- ROCKWELL DIAMOND INDENTORS (HARDNESS TESTERS)

- DIAMOND BURNISHING TOOLS

NATURAL DIAMOND DRESSER

The demands on the grinding process are becoming tougher, both in dimensional and geometrical tolerances and surface quality.

This is where dressing steps in.

Dressing tools for silicon carbide and aluminum oxide wheels must aid in the following aspects,

- In order to eliminate run-out of the wheel and to maintain the accurate geometrical shape.

- Restoring the necessary roughness of the wheel.

- Maintain the wheel grinding efficiency at a higher level.

We have the capability of manufacturing custom dressing tools to client's specification. Extensive emphasis is placed on multi point dressing instruments in light of the fact that these dressing devices as of late have become progressively the tool of choice.

The Diamond points are naturally formed. Natural Point Diamond Dressers have high from retention properties.

Availability: 0.10 Ct to 2.50 Ct.

We offer single point diamond dressers in a wide assortment of shapes and weights. Our re-settable tools have 2 or more resettable points and can be sent back to us for expert resetting at a small amount of the first expense. Our standard or non-re settable tools are discarded after they have been completely consumed.

Multi diamond dressers consist of a number of small natural diamonds of good crystal character, set in a geometric pattern in single layer and sintered into a special wear resistant bond. Usually seven, smaller diamond stones are mounted in spaced relationship across the working surface of the shank.

These tools are available in 2, 3, 5, and 7 stone configurations and on standard, special and tapered shanks. Multi point Diamond Dressers give rapid-dressing and produce a consistent even surface on the grinding wheel. These dressers are resistant to shock and impact. The dressing face of the Cluster Type Diamond Dresser should be set at an angle of 90° to the grinding wheel so that all the diamond points are in contact at the same time.

Impregnated dressers are commonly used to straight dress larger and wider grinding wheels. These tools have a large concentration of diamond grit held together by a strong metal matrix that will allow new fresh diamond grains to present themselves as the tool wears. Some important advantages are,

Lower cost contrasting to the larger carat diamonds.

Higher dressing speed because of the large tool surface.

Convenient, as there is no necessity to rotate this dresser.

Longer tool life.

On most Dia-form machines two dressers are setup for use in tandem and both can be replaced or interchanged easily and quickly. Mounted adjacent to each other either the roughing and semi-finishing and finishing tools can be setup together. Both dressers are inclined at an angle of 5 degrees to the wheel centerline at the point of contact, providing the optimum cutting conditions. Various angles and radii are available on these forming tools.

Chisel dressers are used to form precise profiles on grinding wheels. These tools all comprise of a specific angle and a specific radius. A larger radius is generally used for roughing larger radii and a smaller radius for finishing or producing smaller radii. However unlike the dia-form these chisels need to be indicated for accurate performance. Various shanks, radii, flats and angles are available on these chisels

Conical Tools are elongated diamonds cut to a conical or tapered shape with an angle and radius included on the point. Generally the angle ranges between 60 and 120 degrees. Smaller angles are more delicate, wear faster and break easier than larger angles. These tools are mainly used for step, form and radius dressing. Cone Point diamonds can be manufactured in a variety of shank sizes and lengths.

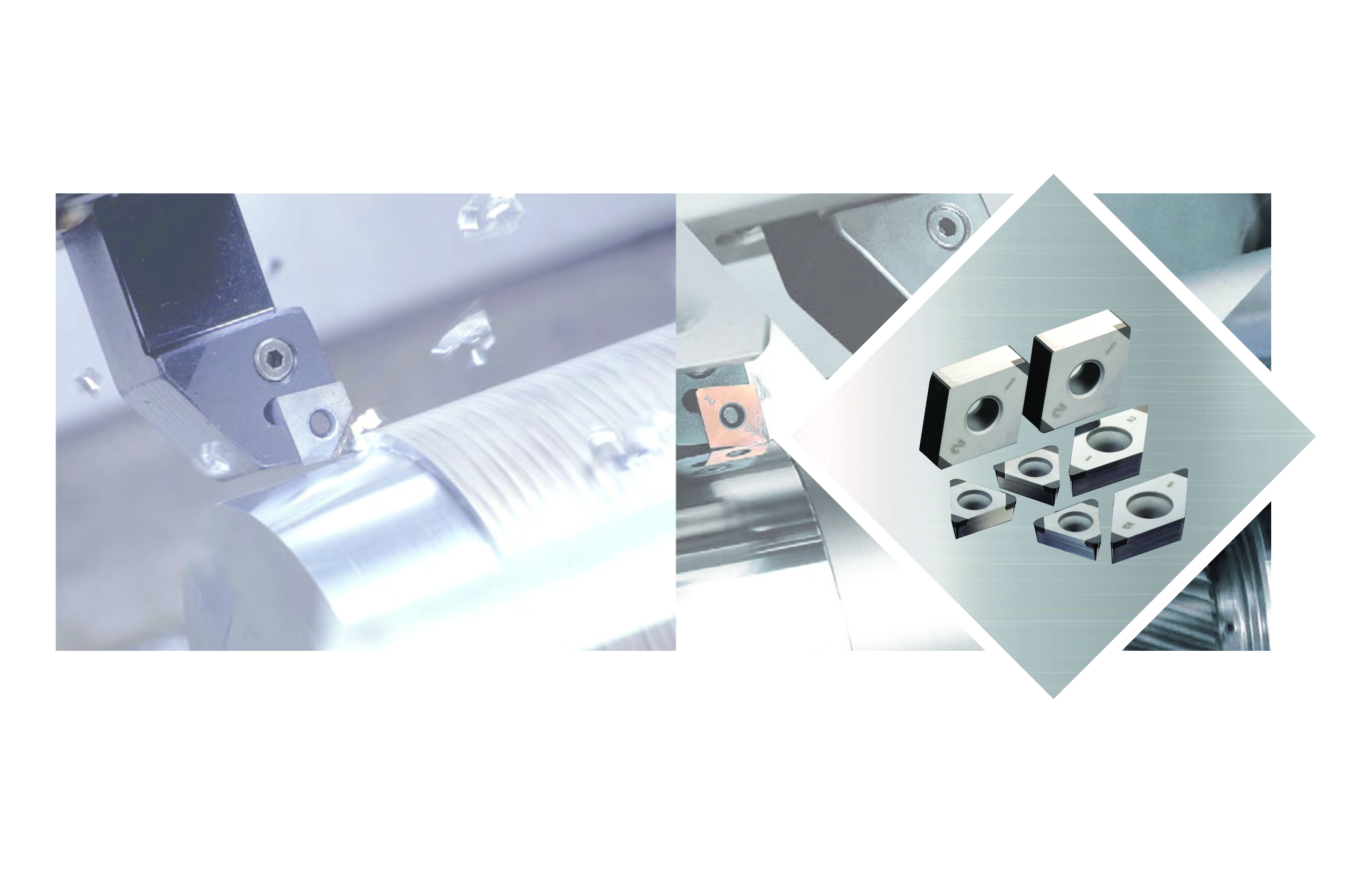

PCD & PCBN CUTTING TOOLS

Our PCD-CBN turning cutter inserts program provides a wide range of ISO tools.

We follow the standard ISO convention for describing insert shape and geometry, for example a 12mm triangle may be designated as follows

T P G B 12 02 02

T = Shape (triangular)

P = Insert clearance angle (11°)

G = Tolerance class (G)

B= Type of insert, i.e., Hole and Chip breakers

12 = Edge length (12mm)

02 = Insert thickness (2.38mm)

02 = Radius (0.2mm)

The cutting speed of PCD grooving tool is greater than that of cemented carbide cutting tools. These PCD grooving tools are used for Milling cast iron, aluminium, copper, Hardened steel, bronze, and heat treated metals for metalworking and automobile industries. Our provided grooving tools are offered in various sizes and specifications as per the needs of our clients. Some important features are compact design, light weight, high accuracy of machining.

Do you have to insert grooves into hardened steel, aluminium, brass, ceramics or another hard to cut material and have a high level of tool wear or long chips? Let us know your task that requires grooving.

These PCD Turning Tools is a synthesised, extremely tough, inter grown mass of randomly orientated diamond particles in a metal matrix. These PCD Turning Tools is produced by sintering together selected diamond particles at high pressure and temperature.

Poly-crystalline diamond (PCD) is used in many cutting operations as a substitute for mono-crystalline diamonds (MCD). Its advantages are in the interrupted cut and in cases of extreme wedge angle geometry. The correct type of PCD for the respective task, polished cut surfaces and the finest ground cutting edges are important characteristics of our tools.

LMDT has developed extensive expertise in the field of PCD and CVD equipped carbide metal milling tools in recent years.

Our wide range of metal milling tools of Ø 1-20mm always ensures the most suitable tool.

By using PCD or CVD milling tools, you considerably increase the service life and reduce the machine downtime in doing so, improve surface finishes and can significantly speed up the milling process.

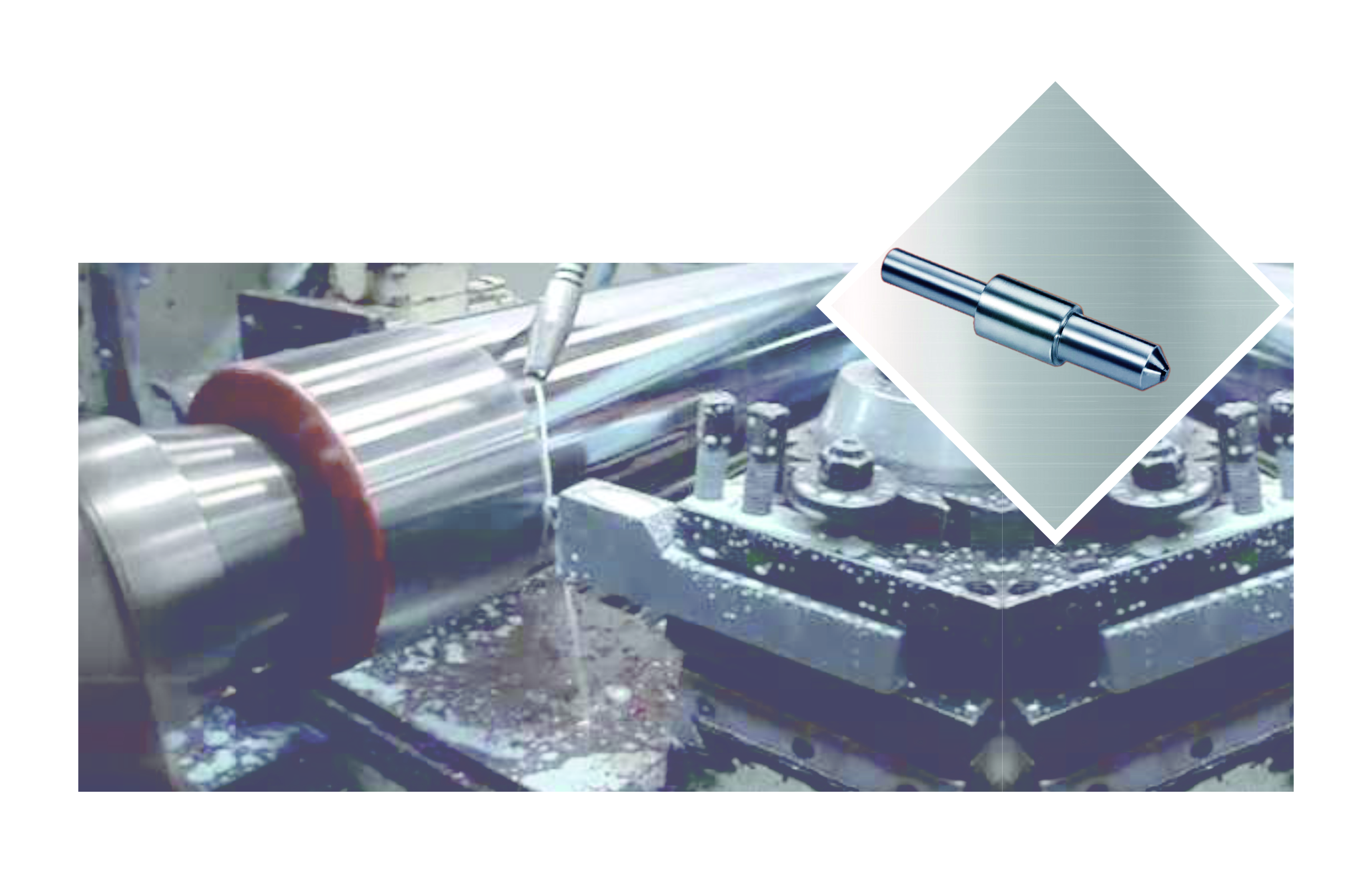

Bore diameters from 1mm can be bored using our PCD or CBN equipped carbide boring tools.

A precisely coordinated intake system with internal cooling and boring tool with cutting surface complete the program.

A 45° inclination on the shaft and a transverse pin in the intake fixture allows you to accurately set the tool for operation in just a few seconds

DIAMOND GAUGING & BURNISHING TOOLS

This is an instrument for measuring hardness by the depth of the indentation by a duly lapped point to strict specification under a given load.

To minimize diamond breakage, we use only the highest quality industrial diamonds. Each Rockwell diamond indenter is ground, lapped and hand polished to control the conical angle to 120° ±0.35°. In order to prevent shift under test loads, the diamond is precisely positioned and then sintered in place.

Diamond burnishing tools is highly regarded as user friendly for producing Mirror finish.

These burnishing tools produce an ultra smooth surface finish on linear surfaces. It is used for Burnishing outer diameter.

.jpg)